by

wecreate

|

October 10, 2018

|

Polycarbonate

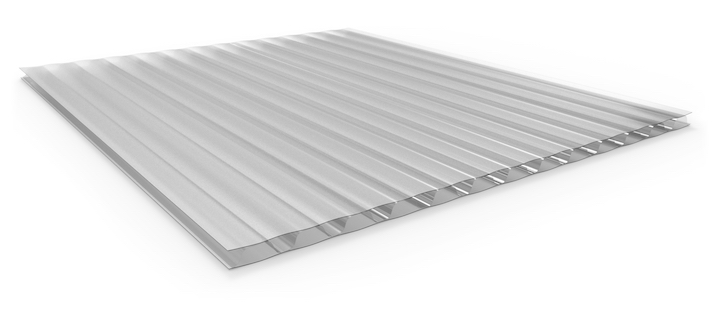

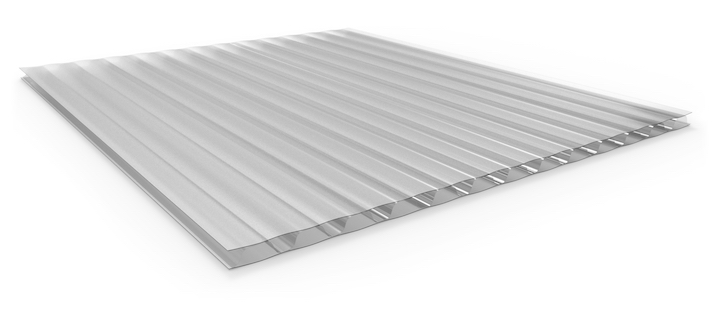

Polycarbonate (PC) is similar to glass and acrylic in clarity but has a significantly higher impact resistance. It is frequently used in machine guarding and security applications that require optical clarity and stronger resistance to breakage. Polycarbonate is lightweight, stiff, and relatively easy to saw, machine, heat form, and paint. It also comes in a variety of colors and grades, including flame-retardant, bullet-resistant, FDA-compliant, structural foam-grade, and glass-filled grades for maximum strength.

Industry trade names: AZCARB, CYROLON, LEXAN, MAKROLON, MARGARD, POLYCAST, POLYGAL, TUFFAK, ZELUX

Common Applications

- Machine guarding

- Windows, windshields, and window well covers

- Power tool and appliance housings

- Skylights and architectural glazing

- Security glazing

- Indoor and outdoor signs

- Greenhouse glazing (twin-wall grades)

Characteristics of Polycarbonate (PC)

- Impact resistant

- Heat and flame resistant

- High clarity

- Wide temperature range

- High toughness and dimensional stability

- Resistant to moisture, humidity, greases, and most acids

Polycarbonate Properties Chart

|

UNITS |

ASTM TEST |

Polycarbonate |

| Tensile strength |

psi |

D638 |

9,000-10,500 |

| Flexural Strength |

psi |

D790 |

11,000-15,000 |

| Flexural Modulus |

10^5 psi |

D790 |

3.0-3.4 |

| Impact Strength, Izod |

ft-lbs/in of notch |

D256 |

12-16 |

| Heat deflection temperature @ 264 psi |

°F |

D648 |

260-270 |

| Flammability rating |

|

UL94 |

HB, V-0 |

| Water absorption (1/8” thick, 24 hours) |

% |

D570 |

0.15 |

| Refractive Index |

|

D542 |

1.586 |

| Light Transmittance |

% |

D1003 |

85-89 |

| Coefficient of thermal expansion |

10^5 in/in-℃ |

D696 |

6.6-7.0 |

| Elongation |

% |

D638 |

110-125 |

Values may vary. Please ask your Erie Industrial Plastics representative for more specific information.

by

wecreate

|

July 12, 2018

|

Uncategorized

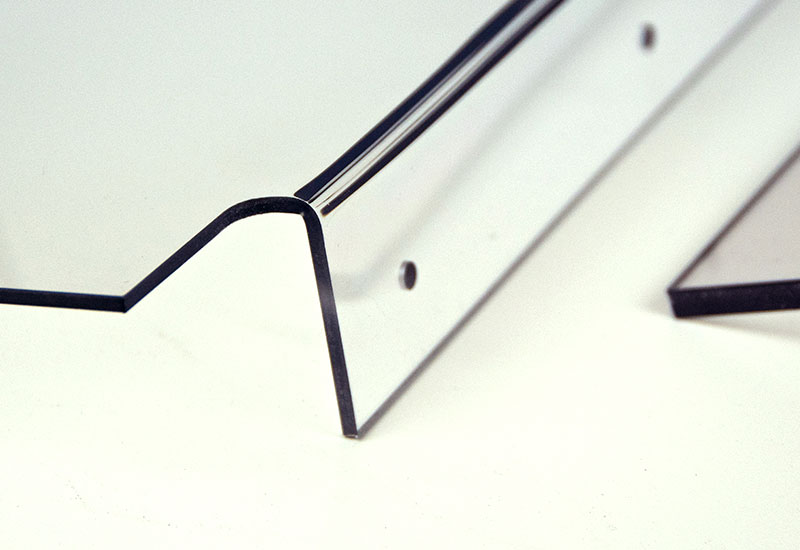

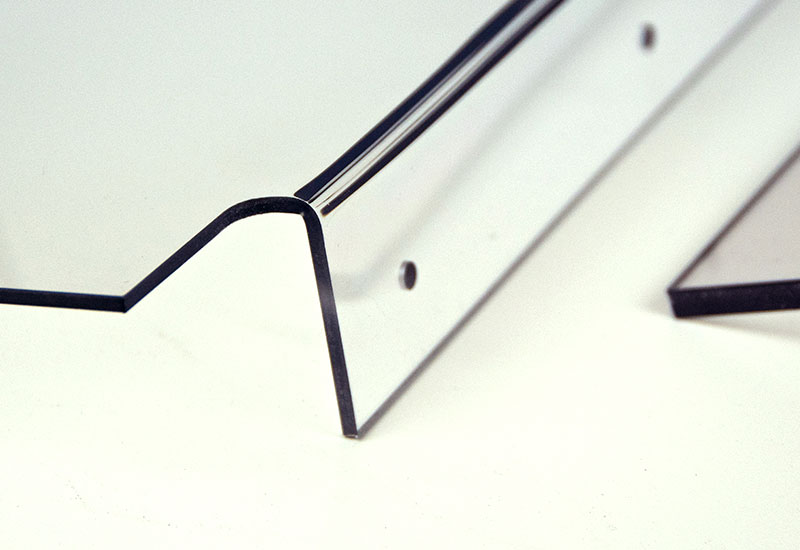

ERIE INDUSTRIAL PLASTICS PROVIDES PLASTIC LINE BENDING SERVICES WITH HRK 125 SERIES LINEAR HEATER

Erie Industrial Plastics currently operates an Edge Finisher HRK125 series linear heat table for bending. With the HRK125, EIP can produce seamless bends for all types of plastic products, including:

- Display cases

- Machine and food processing guards

- Equipment covers and guides

- Protective housing units

- Tray and storage organizers

HRK 125 SERIES LINE BENDING MACHINE—THE ADVANCED MODEL WITH TOP AND BOTTOM HEATING ELEMENTS

The HRK125 series line bender features double-sided heating, adjustable heating wires built into a steel frame, and a programmable timer that automatically releases to provide consistent top and bottom heating. The bending table provides close tolerance plastic bending without any pretreatments and tight radius edges for crisp bends. This equipment is ideal for a variety of materials, including acrylic, ABS, polycarbonate, kydex, copolymer polypropylene, and PETG.

After the line bender heats the material, it is positioned on a JIG to bend to the required dimensions and held together with weights or JIG clamps. The HRK125’s accessories offer various extension options, specially made fixtures, underframes, and foil bending profiles. For more about EIP’s HRK 125 Series, see the video below.

SPECIFICATIONS OF EIP’S HRK 125 SERIES PLASTIC STRIPHEATER

- Heats up to 500℃ | 932℉

- Max working length: 49.25 in | 1250 mm

- Can heat .01-.78 in | 0.3-20 mm thick in 20 seconds

- Bend material up to 20 mm thick

- 8 adjustable heating lines

- Capable of making two close bends

- Wide reflectors for bending large radii

- No water-cooling treatment needed

- Contact heating for thin sheets for various shapes

ERIE INDUSTRIAL PLASTIC’S OTHER PLASTIC FABRICATION SERVICES

We offer many services in addition to plastic line bending. These services include CNC routing, laser cutting and engraving, plastic welding, thermoforming, saw cutting, drilling, edge-finishing, and assembly. We aim to meet our customers’ needs no matter the size of the project.

Recent Comments