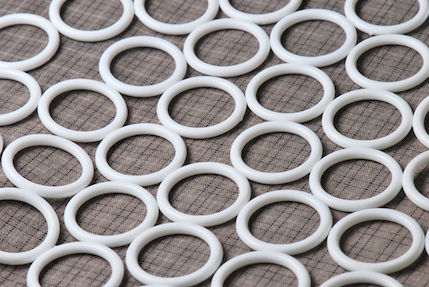

Polytetrafluoroethylene (Ptfe)

Teflon (PTFE) is a high-performance, semi-crystalline thermoplastic that can be used in a variety of applications. It is one of the most chemically-resistant plastics available and has one of the widest temperature ranges, -400°F (-240°C) to 500°F (260°C). It also has excellent insulation properties for thermal and electrical applications. Teflon has a very low coefficient of friction, making it naturally slick and resistant to sticking and bonding. Its mechanical properties are low compared to other high-performance plastics but can be improved by the addition of fillers such as glass fiber, carbon, graphite, molybdenum disulfide, and bronze.

Benefits

- High chemical resistance

- Low and high-temperature capability

- Resistance to weathering

- Low friction

- Electrical and thermal insulation

- Anti-stick surface

Common Applications

- Seals and gaskets

- Packing materials exposed to chemicals

- Bushings, bearings, and slide bearings

- Piston rings

- Wire, cable, and electrical insulation

PTFE | Teflon Properties Chart

| UNITS | ASTM TEST | PTFE | |

| Tensile strength | psi | D638 | 3,350 |

| Flexural Modulus | 10^5 psi | D790 | 0.5-0.9 |

| Impact Strength, Izod | ft-lbs/in of notch | D256 | 3.5 |

| Heat deflection temperature @ 264 psi | °F | D648 | 132 |

| Max Service Temp – Long Term | °F | UL94 | 500 |

| Coefficient of thermal expansion | 10^5 in/in-°F | D696 | 5.5-8.4 |

| Elongation | % | D638 | 300 |

Values may vary. Please ask your Erie Industrial Plastics representative for more specific information.