Polycarbonate (PC) is similar to glass and acrylic in clarity but has a significantly higher impact resistance. It is frequently used in machine guarding and security applications that require optical clarity and stronger resistance to breakage. Polycarbonate is lightweight, stiff, and relatively easy to saw, machine, heat form, and paint. It also comes in a variety of colors and grades, including flame-retardant, bullet-resistant, FDA-compliant, structural foam-grade, and glass-filled grades for maximum strength.

Industry trade names: AZCARB, CYROLON, LEXAN, MAKROLON, MARGARD, POLYCAST, POLYGAL, TUFFAK, ZELUX

Common Applications

- Machine guarding

- Windows, windshields, and window well covers

- Power tool and appliance housings

- Skylights and architectural glazing

- Security glazing

- Indoor and outdoor signs

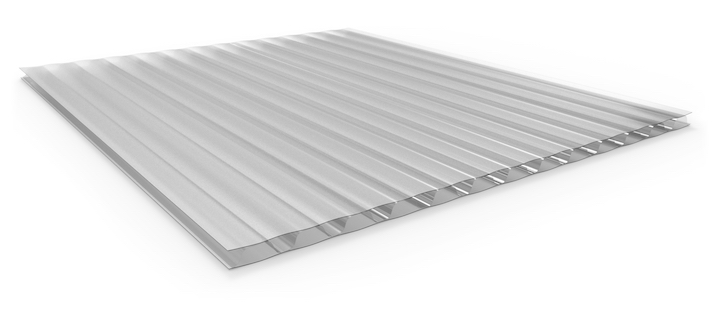

- Greenhouse glazing (twin-wall grades)

Characteristics of Polycarbonate (PC)

- Impact resistant

- Heat and flame resistant

- High clarity

- Wide temperature range

- High toughness and dimensional stability

- Resistant to moisture, humidity, greases, and most acids

Polycarbonate Properties Chart

| UNITS | ASTM TEST | Polycarbonate | |

| Tensile strength | psi | D638 | 9,000-10,500 |

| Flexural Strength | psi | D790 | 11,000-15,000 |

| Flexural Modulus | 10^5 psi | D790 | 3.0-3.4 |

| Impact Strength, Izod | ft-lbs/in of notch | D256 | 12-16 |

| Heat deflection temperature @ 264 psi | °F | D648 | 260-270 |

| Flammability rating | UL94 | HB, V-0 | |

| Water absorption (1/8” thick, 24 hours) | % | D570 | 0.15 |

| Refractive Index | D542 | 1.586 | |

| Light Transmittance | % | D1003 | 85-89 |

| Coefficient of thermal expansion | 10^5 in/in-℃ | D696 | 6.6-7.0 |

| Elongation | % | D638 | 110-125 |

Values may vary. Please ask your Erie Industrial Plastics representative for more specific information.