by

wecreate

|

February 7, 2019

|

Uncategorized

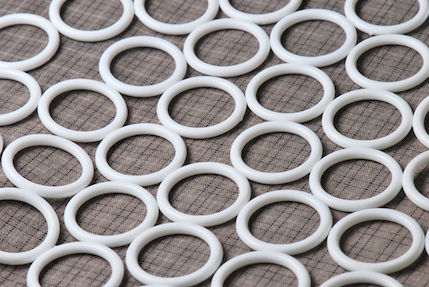

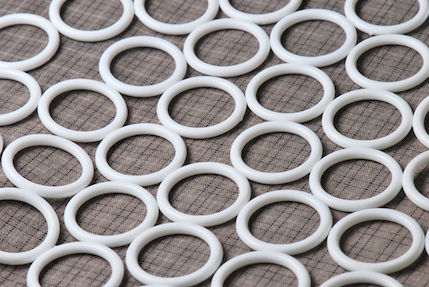

Nylon is one of the most widely used engineering thermoplastics. It is frequently used as a replacement for bronze, brass, aluminum, steel, and other metals, as well as other plastics, wood, and rubber. It offers excellent mechanical performance while being cost effective, lightweight, and noise resistant. In addition, nylon can withstand sustained contact with a wide variety of chemicals, alkalis, dilute acids, and oxidizing agents.

There are many nylon grades available today, the most common being nylon 6/6 and nylon 6. The properties of these products are very similar and they can typically be used interchangeably. With that said, there are some advantages and limitations to each material. For example, nylon 6/6 has a higher melting point (by 70℉ / 21℃) and intermittent use temperature than cast nylon 6 and is less absorbent; however, because of its extrusion processing method, nylon 6/6 is limited to constant cross-section profiles and certain size constraints. Nylon 6 also typically offers better dimensional stability, machineability, and higher compressive and tensile strengths.

Nylons 11 and 12 are also available at a higher price point. These materials typically have lower water absorbency and better electrical properties. Certain additives are available to make these grades more flexible and ductile and they can also be cast.

There are a number of fillers available for nylon materials, the most common being molybdenum disulfide (MD). Nylon MD shares many of the same properties as natural nylon but with added load-bearing capacity, toughness, thermal properties, lubricity, and durability. Some other fillers include glass, oil, and carbon fiber.

Benefits

-

Low friction, self-lubricating, and high resistance to wear, abrasion, and vibration

-

High tensile strength

-

High impact resistance

-

High modulus of elasticity

-

Lightweight

-

Chemical resistance to alkalis, dilute acids or oxidizing agents

*Note: typical grades of nylon are NOT moisture-resistant or UV-resistant and typically have a relatively high coefficient of thermal expansion

Common Applications

-

Rollers, bearings, bushings, and gears

-

Wheels and wear components

-

Seals and washers

-

Sheaves and sprockets

-

Slides and cams

-

Electrical and semiconductor connectors

-

Steel and mining equipment

-

Automotive and transportation equipment

-

Food processing and bottling equipment

-

Sports & recreational equipment

Typical Nylon 6/6 Properties Chart

| |

UNITS

|

ASTM TEST

|

Nylon

6/6

|

|

Tensile strength

|

psi

|

D638

|

12,000

|

|

Flexural Modulus

|

10^5 psi

|

D790

|

440,000

|

|

Impact Strength, Izod

|

ft-lbs/in of notch

|

D256

|

1.0

|

|

Heat deflection temperature @ 264 psi

|

°F

|

D648

|

194

|

|

Max Service Temp – Long Term

|

°F

|

UL94

|

210

|

|

Water absorption (1/8” immersion 24 hours)

|

%

|

D570

|

1.2

|

|

Coefficient of thermal expansion

|

10^5 in/in-°F

|

D696

|

4.0

|

|

Elongation

|

%

|

D638

|

60

|

Plastics international

Values may vary. Please ask your Erie Industrial Plastics representative for more specific information.

by

wecreate

|

November 27, 2018

|

Uncategorized

Polytetrafluoroethylene (Ptfe)

Teflon (PTFE) is a high-performance, semi-crystalline thermoplastic that can be used in a variety of applications. It is one of the most chemically-resistant plastics available and has one of the widest temperature ranges, -400°F (-240°C) to 500°F (260°C). It also has excellent insulation properties for thermal and electrical applications. Teflon has a very low coefficient of friction, making it naturally slick and resistant to sticking and bonding. Its mechanical properties are low compared to other high-performance plastics but can be improved by the addition of fillers such as glass fiber, carbon, graphite, molybdenum disulfide, and bronze.

Benefits

- High chemical resistance

- Low and high-temperature capability

- Resistance to weathering

- Low friction

- Electrical and thermal insulation

- Anti-stick surface

Common Applications

- Seals and gaskets

- Packing materials exposed to chemicals

- Bushings, bearings, and slide bearings

- Piston rings

- Wire, cable, and electrical insulation

PTFE | Teflon Properties Chart

|

UNITS |

ASTM TEST |

PTFE |

| Tensile strength |

psi |

D638 |

3,350 |

| Flexural Modulus |

10^5 psi |

D790 |

0.5-0.9 |

| Impact Strength, Izod |

ft-lbs/in of notch |

D256 |

3.5 |

| Heat deflection temperature @ 264 psi |

°F |

D648 |

132 |

| Max Service Temp – Long Term |

°F |

UL94 |

500 |

| Coefficient of thermal expansion |

10^5 in/in-°F |

D696 |

5.5-8.4 |

| Elongation |

% |

D638 |

300 |

Values may vary. Please ask your Erie Industrial Plastics representative for more specific information.

by

wecreate

|

July 12, 2018

|

Uncategorized

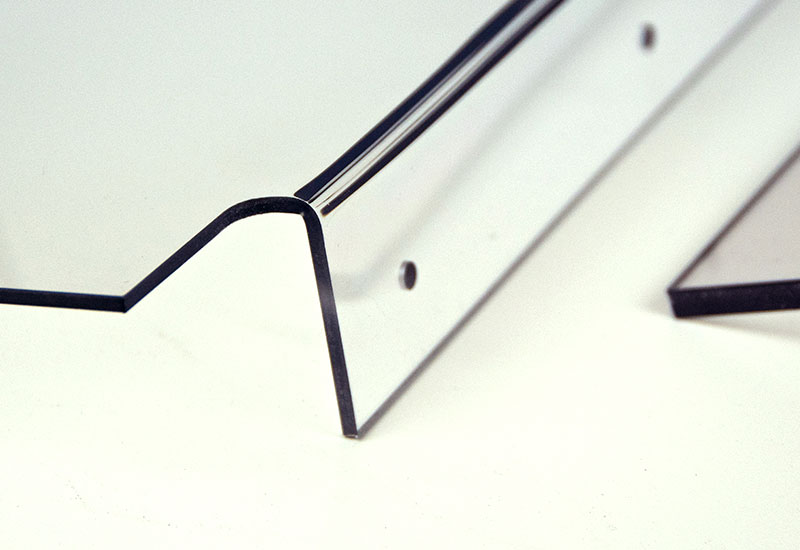

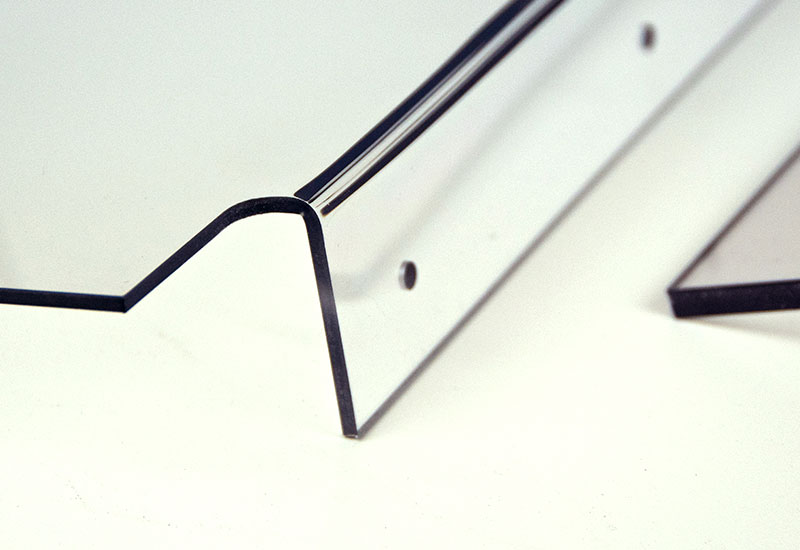

ERIE INDUSTRIAL PLASTICS PROVIDES PLASTIC LINE BENDING SERVICES WITH HRK 125 SERIES LINEAR HEATER

Erie Industrial Plastics currently operates an Edge Finisher HRK125 series linear heat table for bending. With the HRK125, EIP can produce seamless bends for all types of plastic products, including:

- Display cases

- Machine and food processing guards

- Equipment covers and guides

- Protective housing units

- Tray and storage organizers

HRK 125 SERIES LINE BENDING MACHINE—THE ADVANCED MODEL WITH TOP AND BOTTOM HEATING ELEMENTS

The HRK125 series line bender features double-sided heating, adjustable heating wires built into a steel frame, and a programmable timer that automatically releases to provide consistent top and bottom heating. The bending table provides close tolerance plastic bending without any pretreatments and tight radius edges for crisp bends. This equipment is ideal for a variety of materials, including acrylic, ABS, polycarbonate, kydex, copolymer polypropylene, and PETG.

After the line bender heats the material, it is positioned on a JIG to bend to the required dimensions and held together with weights or JIG clamps. The HRK125’s accessories offer various extension options, specially made fixtures, underframes, and foil bending profiles. For more about EIP’s HRK 125 Series, see the video below.

SPECIFICATIONS OF EIP’S HRK 125 SERIES PLASTIC STRIPHEATER

- Heats up to 500℃ | 932℉

- Max working length: 49.25 in | 1250 mm

- Can heat .01-.78 in | 0.3-20 mm thick in 20 seconds

- Bend material up to 20 mm thick

- 8 adjustable heating lines

- Capable of making two close bends

- Wide reflectors for bending large radii

- No water-cooling treatment needed

- Contact heating for thin sheets for various shapes

ERIE INDUSTRIAL PLASTIC’S OTHER PLASTIC FABRICATION SERVICES

We offer many services in addition to plastic line bending. These services include CNC routing, laser cutting and engraving, plastic welding, thermoforming, saw cutting, drilling, edge-finishing, and assembly. We aim to meet our customers’ needs no matter the size of the project.

Recent Comments